Industry 4.0 Evolution Blockchain’s Manufacturing Impact”

Industry 4.0 Evolution: Blockchain’s Manufacturing Impact

In the realm of manufacturing, where precision and efficiency are paramount, the advent of Industry 4.0 is a game-changer. At the forefront of this revolution stands blockchain, an innovative technology that is reshaping the manufacturing landscape and propelling it into a new era of digital transformation.

Smart Factories: Blockchain Reshaping Manufacturing

Gone are the days of traditional manufacturing processes. Blockchain is ushering in the era of smart factories, where every aspect of production is interconnected and optimized for efficiency. The integration of blockchain technology into manufacturing systems creates a seamless and transparent network, fostering real-time communication and collaboration between different stages of the production line.

Innovative Production: Blockchain in Manufacturing Mastery

Blockchain’s mastery in manufacturing lies in its ability to innovate production processes. By creating a decentralized and tamper-resistant ledger, blockchain ensures the integrity of data throughout the manufacturing lifecycle. This innovation translates into improved quality control, reduced errors, and a more streamlined production flow.

Supply Chain Transparency: Blockchain’s Manufacturing Revolution

One of the revolutionary aspects of blockchain in manufacturing is its impact on supply chain transparency. Traditional supply chains often suffer from opacity and inefficiencies. Blockchain addresses these issues by providing a transparent and immutable record of every transaction and movement within the supply chain. This transparency not only reduces the risk of fraud but also enhances overall accountability.

Digital Transformation: Blockchain’s Role in Modern Manufacturing

The digital transformation of manufacturing is underway, and blockchain is playing a pivotal role in this shift. From digitalizing records to automating processes, blockchain is enabling manufacturers to embrace modern technologies that enhance productivity and reduce operational costs. This digital transformation positions manufacturing at the forefront of Industry 4.0.

Revolutionizing Production: Blockchain in Manufacturing Networks

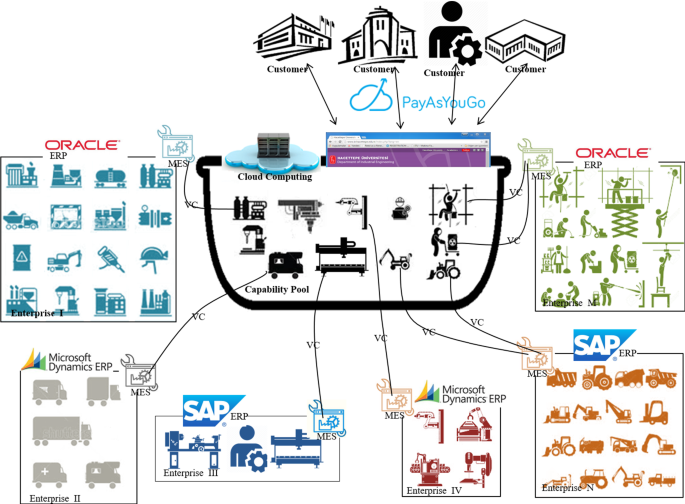

Blockchain’s impact extends beyond individual factories; it revolutionizes the entire manufacturing network. Through a decentralized network, manufacturers can collaborate seamlessly, share information securely, and even automate transactions through smart contracts. This interconnectedness fosters a collaborative ecosystem where efficiency and innovation thrive.

Streamlined Processes: Blockchain’s Manufacturing Efficiency

Efficiency is the cornerstone of successful manufacturing, and blockchain is the catalyst for streamlined processes. By eliminating intermediaries and automating trust through its decentralized ledger, blockchain reduces delays and costs associated with traditional manufacturing workflows. This efficiency allows manufacturers to respond swiftly to market demands and optimize resource utilization.

Manufacturing Resilience: Blockchain’s Impact Unveiled

In an era where resilience is key, blockchain unveils its impact by fortifying manufacturing against disruptions. The decentralized nature of blockchain ensures that even in the face of unexpected challenges, such as supply chain interruptions or unforeseen events, the manufacturing process remains resilient. This adaptability is a testament to the robust and tamper-resistant nature of blockchain’s distributed ledger.

Next-Gen Factories: Blockchain’s Manufacturing Evolution

The evolution of manufacturing into next-gen factories is marked by the integration of blockchain. These factories leverage blockchain technology to create a secure, transparent, and interconnected environment where data flows seamlessly across the production line. This evolution represents a paradigm shift in how factories operate and underscores the transformative