Unveiling the Power of Centrifuge Cryptocurrency Solutions

Centrifuge Crypto: Redefining the Future of Digital Transactions

In the ever-evolving landscape of digital finance, Centrifuge Crypto emerges as a dynamic force, reshaping the way we perceive and conduct secure transactions. Let’s delve into the intricacies of this innovative cryptocurrency and explore how it’s revolutionizing the financial industry.

The Centrifuge Advantage: Revolutionizing Security

At the heart of Centrifuge Crypto is a commitment to revolutionize security in digital transactions. Unlike traditional cryptocurrencies, Centrifuge places a premium on robust security measures, ensuring that users can engage in transactions with confidence, free from the constant worry of cyber threats and vulnerabilities.

Efficiency Unleashed: Navigating Transactions with Centrifuge Crypto

Centrifuge Crypto doesn’t just stop at security; it’s equally focused on efficiency. Navigating transactions with Centrifuge is a streamlined experience, reflecting the currency’s dedication to providing users with a seamless and efficient platform for their digital exchanges. It’s about making financial transactions effortless and swift.

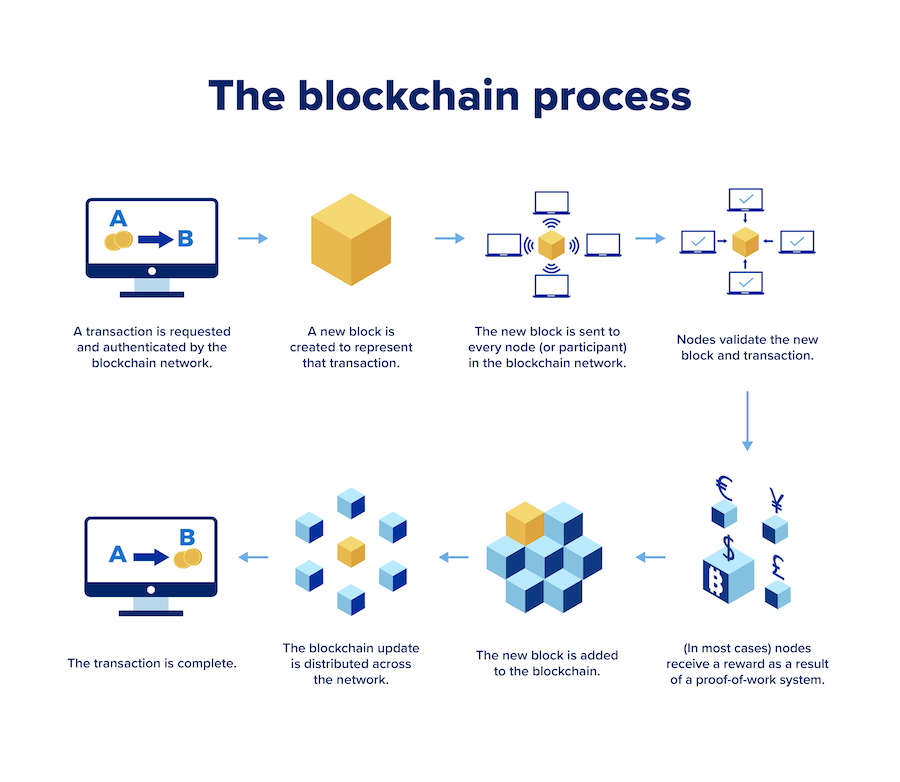

Centrifuge Blockchain: Shaping the Future of Digital Finance

At its core, Centrifuge Crypto relies on a sophisticated blockchain infrastructure. This technology is not just a foundation; it’s a catalyst for reshaping the future of digital finance. The decentralized nature of Centrifuge Blockchain adds an extra layer of transparency and trust, setting it apart in the crowded crypto space.

Building Trust and Efficiency: Centrifuge Cryptocurrency Networks

Centrifuge Cryptocurrency Networks embody a fusion of trust and efficiency. By establishing secure and transparent platforms, these networks pave the way for a new era in financial transactions. Users benefit from the confidence that their exchanges are not only efficient but also conducted within a trustworthy ecosystem.

Innovation Unleashed: Centrifuge Crypto Networks

Centrifuge Crypto Networks are at the forefront of financial innovation. These networks don’t just follow trends; they set them. By embracing cutting-edge technologies and approaches, Centrifuge Crypto Networks create an environment where users can experience the future of digital finance today.

Securing Digital Transactions: Centrifuge Blockchain Integration

Centrifuge Blockchain Integration goes beyond just providing a secure environment for transactions. It represents a strategic fusion of security and innovation. The integration ensures that users experience the utmost security while navigating the digital landscape, setting a new standard for the security of digital transactions.

Transparent Exchanges: Centrifuge Digital Currency Solutions

Centrifuge Digital Currency Solutions contribute to a financial ecosystem marked by transparency. Transparent exchanges are not just a feature; they’re a commitment. Users can track and verify transactions effortlessly, fostering a sense of openness and accountability in every financial interaction.

Empowering Financial Journeys: Centrifuge Digital Currency

Centrifuge Digital Currency doesn’t merely serve as a means of financial exchange; it empowers financial journeys. By providing a secure and efficient tool, Centrifuge ensures that users have the confidence to navigate their financial landscapes, knowing that they are supported by a robust and trustworthy digital currency.

Centrifuge Crypto Integration: Building Trust in Digital Finance

Centrifuge Crypto Integration is more than a process; it’s a philosophy. It’s about seamlessly integrating Centrifuge Crypto into the fabric of digital finance, creating an ecosystem where trust is paramount. It’s a testament to